In business, every product launched to the market has to pass some set of requirements. There are general procedures, such as user experience research and product testing, that are usually used to determine the viability of a product before it’s sent out to the consumer market. All these procedures are aimed at improving business efficiency by meeting client’s needs as much as possible.

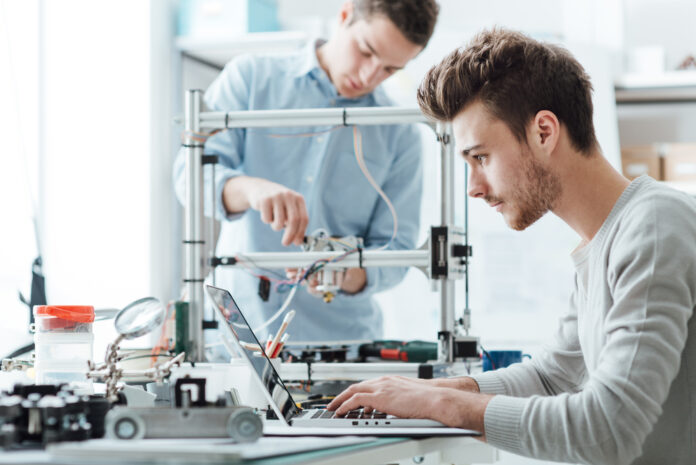

However, there are other options in product development that businesses can utilize to improve the results of their products. Such options include material model development and prototyping. Using these options, businesses can develop mock models to test products’ physical and behavioral aspects under different circumstances before launching them out to the market.

Before, only the physical model of materials could be tested, but this didn’t give the developers a better understanding of how such products could react in certain cases like stress. However, technology has made it possible for a business to model various things they couldn’t before.

How Technology Has Improved Material Modelling

Technology has had several benefits to the financial and industrial process. In model making, it’s now possible to get better results using technology that previously wouldn’t be achieved.

Here are some of the ways that technology has improved model development:

- Behavioral Analysis: When products are developed, the performance isn’t only limited to the physical aspect. For example, when developing shin guards in sports, you need to understand how they’ll react to stress and how long they can withstand such cases. With technology, it’s possible to test the viscoelastic behavior of the materials used to create the shin guard, allowing manufacturers to develop a more efficient end product.

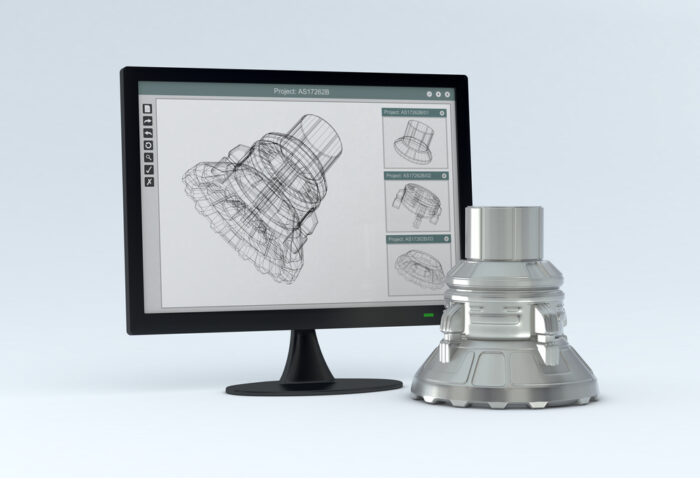

- Modeling Accuracy: Another aspect of material modeling that has been significantly improved by technology is modeling accuracy. Remember, a product prototype is always the first of a kind, which means it has to be as close to the intended product as possible. In such cases, physical modeling couldn’t give you accurate results. However, with computer-aided engineering (CAE), it’s possible to get more accurate models with much finer details.

- Speed Modeling: When product developers want to develop a product, they always have different designs of the end product in mind. Technology has made it possible for them to develop several designs of the same product quickly, allowing them to test the efficiency of each and choosing the right one. Additionally, they can easily make changes to the models developed, ensuring that they end up with a more efficient prototype to be used in the actual product design.

All these technological features have made it possible for businesses to develop models and prototypes that help in better product development and improve efficiency.

How Modelling Materials Can Improve Business Efficiency

In your business, whether you’re a startup or an already established company, you need to test how your product is going to perform. If you have a novel idea or want to compete against similar products, you need to be fully aware of the market forces. Identifying a gap in a consumer market won’t always translate to the success of your product if you don’t commit to the proper testing before channeling your resources to the actual products.

This is why modeling is important to any business in the following ways:

1. Guide the Production Process

Another advantage of having a material model is that the production process is no longer guided by theoretical ideas but a physical representation. This makes it simple for your team to develop the product as they already know what it should look like.

Additionally, with a model, you can assemble the right team and all the required materials used in the development. This helps streamline operations in your business and even save time during production. Every team member will know their roles, what steps to take, and how to bypass challenges as they arise, allowing the companies’ operations to run smoothly.

Developing a model can also help the team realize that what they seek to develop isn’t achievable. For example, if you want to provide software as a service, a model will help you realize that your software doesn’t work correctly with particular hardware or device. You can then adjust your design to meet all the targeted devices.

2. Helps Test Customer Interest in Your Product

The ultimate goal for a business is to create a product that people will be interested in buying. If you first decide to develop the products without testing how customers will receive them in the market, it could cause significant losses to the company, crippling the business.

Modeling the material first before the actual product can help you determine how it’ll be received in the market. For example, if you want to develop software, you can first develop a prototype and then send it to different people to test it and provide feedback. If the feedback is positive, you can then channel more funds into the development and marketing as you’ll be sure about customers’ interest.

If the people in the testing period perceive your product otherwise, it’s safe to change it or look into a more viable option.

3. Modeling Can Test Your Team’s Ability

Another critical aspect of an efficient business is having a team that can handle a task given to them with little to no struggle. If you want to develop a product, you’d want to have a skilled, committed team and responsible enough to bring the idea into realization. Of course, you expect that the team you’ve worked with before is up to the task, but what if your new idea is more complex? How do you determine if you have the right team?

This is where the modeling part of the product helps you assemble the right team. You’ll test if your potential team can develop the product, how long they take, the challenges they face, and how they bypass those challenges. Using this data, you can either assemble a new team or train the current team before embarking on mass production.

Do note that the product has to meet all sets of requirements, and your team should be able to deliver that.

4. Secure Funds from Investors

It’s advantageous if your business is stable enough to finance itself during the production process. However, if you’re looking for external investors to chip in and finance your operations, you need to be crisp in your pitches for them to be confident in your project and invest in your business. Word of mouth won’t always do the trick as you need something more tangible that can help them understand what you’re developing and why you need their money. For some, seeing is believing, and what better way to do it other than a model.

With modeling, you can show investors how your product will interact with the real world and how it’ll solve consumer problems. If they think the product will be viable, then they’ll give you the finances. However, if they think the project won’t succeed, they won’t give you the funds, and you can take the lessons instead.

5. Proper Resource Allocation

The efficiency of a business is also determined by how resources are allocated. For a new product being launched, a lot of resources can be channeled to places such as funding the development and the marketing programs. This is a wise decision if you’re sure that the product will be successful. Otherwise, it may cause significant business failure.

Therefore, you need to make more informed decisions when allocating your resources towards a project. By modeling a material before mass production, you’ll be aware of whether it’ll be a success or not. You can then decide if it’s worth investing in.

Moreover, you can estimate the cost of developing one unit of the product through the model, allowing you to determine the overall budget needed. You can also make better decisions with other resources, such as time and labor. More viable projects will get more resources and vice versa.

6. Meet Consumer Requirements

Businesses create products for consumers, hence it’s important to meet customer requirements as much as possible. Procedures such as user experience testing can help you answer the question, what do customers want? You can then incorporate the feedback into the development cycle and give them what they need.

However, it’s also possible to first develop a model that seeks to meet these requirements. Customers will provide additional feedback, and you can incorporate each one of them in the model before advancing to the next stage of mass production. This will ensure that you know what features to add when you start. This is better than trying to add these features when the development has already started.

Conclusion

Material modeling has become a very important part of businesses. Unlike before, where modeling and prototyping may have been limited, better technology can help businesses model materials and products before actual production.

With the correct models, businesses can make more informed decisions regarding resource allocation and the development cycle. Also, they can get more funds from investors and meet customer’s requirements. All of these are important in boosting business efficiency. An efficient business will always be a successful one.

Find a Home-Based Business to Start-Up >>> Hundreds of Business Listings.