There are a number of manufacturing techniques being employed by the industrialists these days all over the world in order to produce better and effective products. Mainly a manufacturing technique depends upon the nature and quantity of the product being produced. Injection molding is one such technique being used by manufacturers to produce parts by the injection of molten metal inside the mold of specified shape. It basically uses a ram plunger that forces in the molten metal into the cavity which is then solidified into the required shape.Injection molding can be used for a variety of products such as metals, glass, thermosetting polymers, etc. The injection molds cost also varies with the type of the material. Aluminum molds and plastic injection molds are being used in the automobile and aerospace industry these days in order to produce complex parts repeatedly. Generally, injection molds cost is the combination of part complexity, part size, the material used and the quantity of the product being produced.

Injections Molding

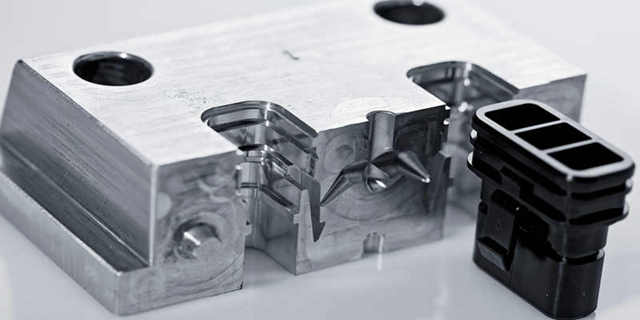

Injection molding is a modern manufacturing technique used in industries where a large number of parts are produced repeatedly. It is an ideal process to produce massive amounts of identical products in less time. Injection molding consists of high-pressure injection of molten raw material in the cavity/mold of the specified shape which then solidifies into the shape as confronted by the mold. Molds are mostly made up of structural or stainless steel which may be of a single cavity or multiple cavities. In multiple cavities, each cavity might be the same and produce the same parts or be different and produce different parts. Injection molds cost of multiple cavity molds is less compared to a single cavity mold. Injection molding includes two types, depending upon the material used: 1) Aluminum injection molding 2) Plastic injection molding

Injection Molding Machine

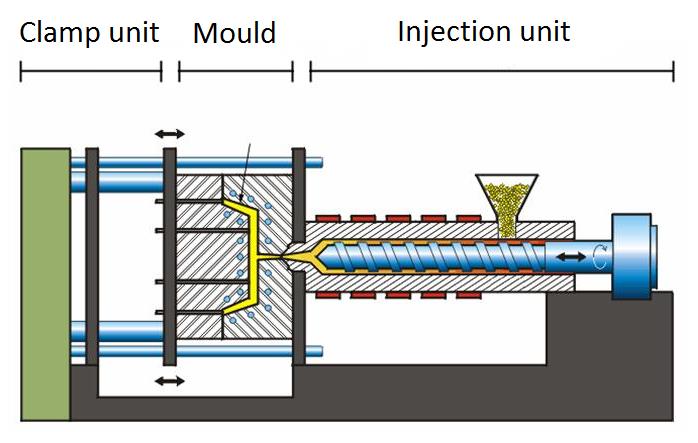

An injection molding machine comes with the ability to pour the molten metal into the cavity and a clamping unit to keep all the parts stationary. The injection unit usually consists of certain parts:

- Feed hopper

- Screw/injection plunger

- Heated barrel

While the clamping unit is made up of the following parts:

- Mold

- Clamping motor drive

- Tie rods

Plastic is usually placed inside the hopper and is responsible for providing the plastic granules for the product to the heated barrel. The machine is almost the same for both aluminum molding and plastic molding with slight changes in the molds and the cavity. The material is heated in the heated barrel by utilizing the friction of screws and the heating of heater bands. It is injected into the cavity by a nozzle. The pouring of molten metal is the critical part of the manufacturing because the material will solidify and will adopt the shape of the mold or cavity. The injection molds cost might increase if the molten metal is poured in the wrong way into the cavity.

The injected metal is then solidified as the configuration of the cavity. After the solidifications, mold mounts opens and the produced parts are ejected out of the machine using ejector pins.

The injection molding machines are of three types depending upon the type of the driving system being used in them:

- Hydraulic

- Mechanical

- Electrical

Nowadays, modern machines also contain a hydraulic arm that is used to mold products side by side, reducing the injection molds cost.

Injection Molds Cost

The injection molds cost factor is greatly dependent upon the complexity of the product and the material that is being used to manufacture the product. Injection molds cost is the combination of part complexity, part size, the material used and the quantity of the product being produced. The selection of single or multiple cavities also impacts the injection molds cost. Usually, if the production amount is smaller, then a single cavity is preferred by the manufacturers. On the other hand, if a manufacturer has to produce a large number of repeated or different parts, multiple cavities will be used which will reduce the injection molds cost.

Material selection is another factor impacting the injection molds cost. The material differences will require molds to be made up of a different material which is costly. The need of usage of plastic or aluminum in the manufacturing of product will enable the manufacturer to buy aluminum casting molds or plastic casting molds. So it is better to estimate the number and type of product to be manufactured before so that required molds can be bought. Following are some of the design considerations which will decrease the injection molds cost:

- Reuse other molds after modifications

- Use a mold with several cavities

- Consideration of part size

- Usage of over-molding

- Eliminate undercuts

- Get rid of unnecessary features

- Use a core cavity approach

Benefits of Injection Molding

Injection molding is one of the most versatile manufacturing methods used by manufacturers all around the world. It is one of the most preferred manufacturing methods due to its advantages. Some of the advantages of injection molding are listed below:

1. Higher Efficiency

Once the manufacturer designs the molds according to the product’s specifications, the molding process is the least time-consuming. A great number of parts can be manufactured by the same mold making it a cost-effective and an efficient manufacturing technique.

2. Production of Complex Geometry with Ease

Injection molding is a cheaper method to produce complex geometries and highly detailed parts. In injection molding, the pressure is applied to the molten metal against the mold due to which highly detailed parts can easily be manufactured. Moreover, the application of pressure on the material is also helpful in producing complex geometries which would be either difficult to produce or expensive to produce.

3. Strength Enhancement

Injection molding employs the use of filler which reduces the density of the molten metal enhancing the strength of the final product. So injection molding has a wide range of applications in the field where parts of high strength are required. Aluminum injection mold is used in automobile industries nowadays to produce aluminum parts repeatedly.

4. Less Manufacturing Cost

The usage of the same mold for the production of a large number of copies make injection molding a cheaper option for high-strength products. Moreover, the introduction of automation in this manufacturing technique has replaced human labor with robots which are able to control the machines with greater efficiency, also reducing the labor cost. Hence a cheaper manufacturing technique is available to the industrialists by the introduction of automation.

Concluding Remarks

It can be concluded that injection molding is one of the most widely used manufacturing processes being employed all over the world. The reduction in the injection molds cost has also aided in its adoption by industrialists. Introduction of automation and production of highly detailed and complex parts are reasons that this method will be the most used manufacturing technique.

Find a Home-Based Business to Start-Up >>> Hundreds of Business Listings.

Hi there. Thanks for sharing the valuable information. I found this article very helpful. Would love to read more from you. Keep up the good work.

I have read a similar article onknowledgenile. com/blogs/how-does-modern-note-taking-approach-moulds-with-digital-revolution Please do check it out.