Anybody who is creative with a calculative mind can launch a prototype design business. Creating prototypes requires ingenuity as well as the ability to notice small details. The following are some of the essential things you need to start a prototype design business.

1. Get a talented team

There are good people all around the world with various backgrounds and experiences. There are many college-educated individuals with technical degrees who you can hire. Another thing that you should look for when hiring your team is communication skills. You should hire somebody with excellent communication skills since they will be in direct contact with the clients and the skills will also make communication easy among the team members.

2. Find the right hardware

Hardware can be very expensive. Large investments can be scary to make considering how quickly technology develops each year. No business owner wants to buy an expensive piece of equipment that will be useless in a couple months. In the prototype business, you require three big pieces of equipment:

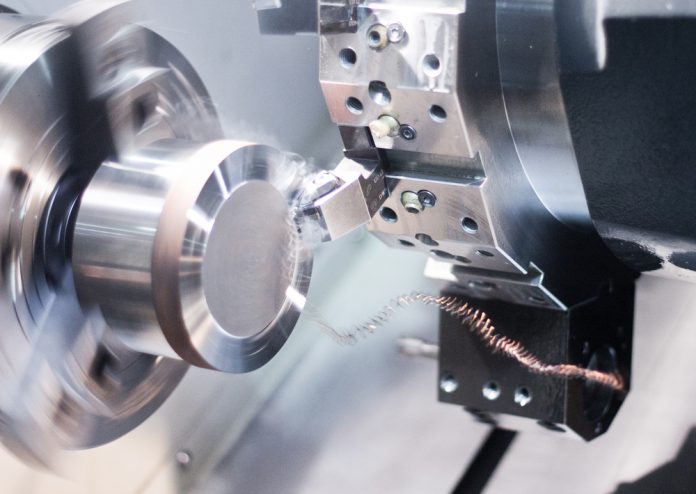

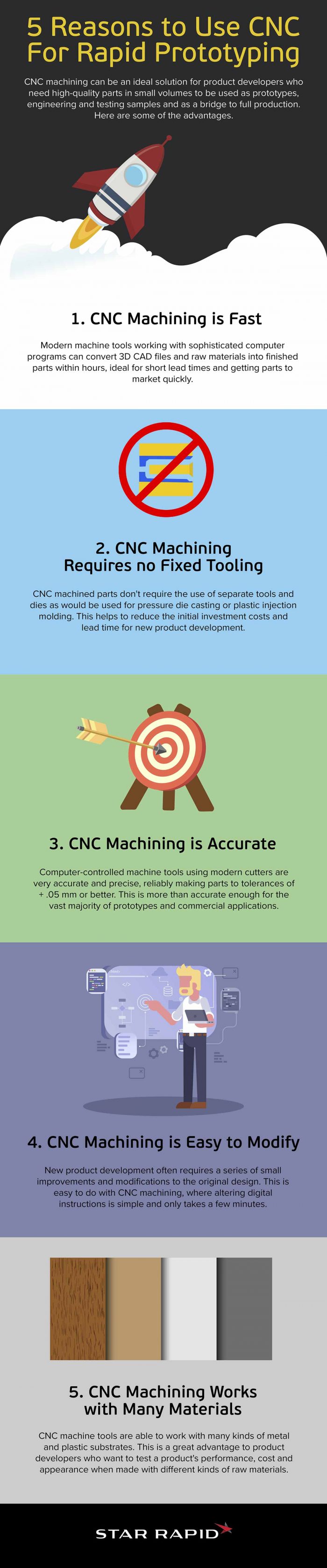

- A Single-tool Programmable CNC Machine

Now people can program a CNC machine to automatically do work that used to require hands-on work by a professional.

- Multi-tool CNC Machine

CNC machines that change tools on their own can engineer complicated parts while you are away. There are many levels of modern CNC machines, and the price and capability depend on how many tools they have.

- Fused Deposition Modeling [FDM] 3D Printer

Fused Deposition Modeling [FDM] machines basically work by taking a given material in filament form, heating it into small drops of liquid material, then printing it according to the software design instructions. A FDM machine cuts down on development time, allowing for quicker testing until arriving at the final solution.

If you have a small amount of startup capital, you can rent the above equipment at any CNC shop such as Star Rapid. This will require adhering to the store’s schedule but it is less expensive than purchasing it and maintaining it over time. You will only rent it on an as-needed basis.

Moreover, you can start with only an advanced 3D printer. Although the business will eventually require a CNC machine, a capable 3D printer will build some prototypes itself. You can start by making only these prototypes, and once the business has enough funds for a CNC machine, you can expand into other work.

3. Get the right software

In today’s world, mechanical design necessitates that people use Computer-Aided Design [CAD] software. Some software can allow for 3D design, animation, and modeling. They can also enable you to run an advanced Computer-Aided Engineering [CAE], Finite Element Analysis [FEA], and Computational Fluid Dynamics [CFD]. You should choose software that is designed properly to avoid mistakes that can be catastrophic to your budget.

4. Find customers

Getting customers is usually one of the hardest things when it comes to business. The customers can lead you down to the path of success or failure. You can start getting customers with a portfolio of a project you have done from a previous job. You can also get referrals from a network of friends and family that know what you can do.

One of the biggest challenges people in prototype businesses face is the price pressure from competitors. Some manufacturers are willing to provide design devices for free as long as they get the right to produce the final product. This makes it difficult because, of course, you can’t compete with “free.” So you have to ensure that you focus on quality.

Find a Home-Based Business to Start-Up >>> Hundreds of Business Listings.