CNC machining (Computer Numerical Control) is machining done by programmed computers using specific software. You’ve probably seen many products made as a result of CNC machining in your everyday life. From the billions of cars on the road to the granite countertops in your kitchen, these products and more are made as a result of CNC machinery. Many industries depend on CNC machinery and society at large would be a lot different if CNC machinery wasn’t around today.

How CNC Machines Work

CNC machines replicate what hand tools and traditional machines do but with computers. CNC machines work by transforming stock material such as wood or aluminum into a product. To start, a CAD (Computer Aided Drawing) drawing would be made with computer software such as AutoCAD, and from there it is sent to the CNC machine where the drawing is translated into computer code. The computer code behind CNC machinery is called G-code. G-code allows you to control certain behaviors of the machine such as the speed and position of the machine. In short, G-code is the instructions given to the machine that tells it how to make the product.

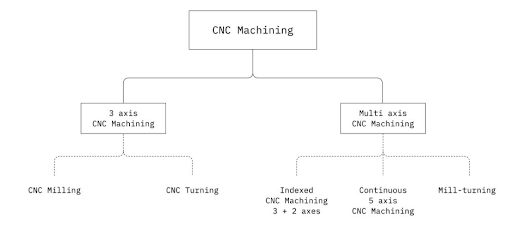

Types of CNC Machinery

Just as making many products require several different parts and tools, there are several different types of CNC machinery. According to the CNC Swiss Style Lathe Toronto experts, the most popular CNC machines are drills, lathes, and mills. CNC drills work by drilling holes into the product. CNC lathes cut materials in a circular motion. CNC milling use rotary cutters to transform material into product. Whereas lathes cut material while it is in motion, mills cut material while it is stationary. Other popular CNC machines include water jet cutters, plasma cutters, and EDM (Electric Discharge Machines) machines.

Advantages of CNC Machining

CNC machines provide many advantages to the businesses that use them. CNC machines are not only major time savers, but also eliminate human error, as the computer programs are very accurate. This allows for many parts to be mass produced very quickly and accurately. Also, unlike humans, CNC machines can work all day if needed. With the machines doing the bulk of the work, human workers can focus on other tasks.

How to Get a CNC Machining Quote

CNC machining is necessary in many businesses, but come at a hefty price. Even though these machines pay for themselves, maybe your business just can’t seem to justify the initial cost. That’s where 3D Hubs comes in. 3D Hubs is the world’s largest network of manufacturing services. Founded in 2013, 3D hubs has production facilities connected in over 140 countries and have produced and shipped over 2 million parts worldwide. The process is simple; You upload your CAD designs and from there you will receive an instant quote for your CNC machining parts. Next to CNC machining 3D Hubs is also active in online 3D printing service. After payment you should receive your parts within 5 to 15 business days. Visit their website at 3dhubs.com to get a CNC quote and see what else this company has to offer.

Furthermore, you can choose to acquire a pre-owned machine for your plant. As you can assume, the price of one of these is considerably lower in comparison to a new one, with the advantage of being able to amortize its acquisition cost quickly. You can look for some interesting options provided by companies specialized in used CNC machinery. Get in touch with the store staff, evaluate the different options, and decide if any of their machines can satisfy your business needs.