Operating in the product industry comes with innumerable concerns that can affect someone’s level of success. This is because everything from the original idea to the final delivery has to go smoothly to ensure customer satisfaction. In order to achieve high retention rates, the company’s performance must be up to par consistently. What is a good way to set up a lucrative, product-based venture?

Creation of Product According to Universal Manufacturing Corp.

In order to see success in this market, one must begin by creating a winning product. Assuming that the idea already exists, it is important to spend the necessary time researching the best manufacturing options. After all, the degree of quality in production will dictate the degree of profitability that can be expected. The easiest way to get started is to focus on the manufacturing side of the blueprint. Doing so can be broken down into a few simple steps that will ensure one gets their product made according to their original vision.

Working on the Prototype

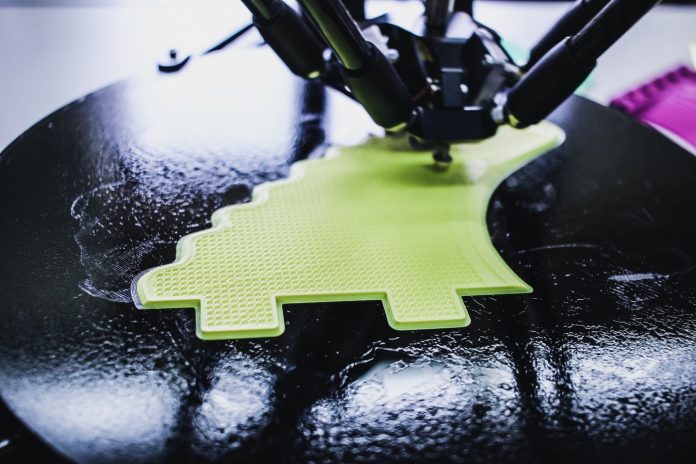

According to a global manufacturing company located in Westchester, Illinois, Universal Manufacturing Corp., the creation of the prototype is one of the most significant steps in the process. For those unfamiliar, a prototype is a preliminary model based on which future units will be developed. Thus, any issues that may exist in this stage must be resolved in order to avoid perpetual setbacks later on. Moreover, a prototype can be very useful for companies that are looking to explore advanced methods of production such as 3-D printers.

Discussing the Manufacturing Location

As expected, one of the most important questions that must be raised pertains to the location of the manufacturer. The reason why this can be a difficult choice is due to the advantages and disadvantages of having domestic producers. For example, relying on a manufacturer from the United States may ensure easier communication and faster delivery. The margin of error would be very small. The problem, however, is the fact that domestic producers will often charge more than their international counterparts. Just think about the number of companies that outsource their needs to China or Mexico.

Negotiating with the Manufacturer

Although one can easily find dozens of manufacturers in almost every country around the globe, picking the best one takes time. This is because there must be a period where the parties negotiate. Some questions that should be asked are:

- What is the manufacturer’s quote on the contract?

- What type of track-record do they have with similar ventures?

- Will there be contingencies and guarantees in place to protect the buyer?

Of course, the list of important inquiries goes on. Nevertheless, starting the conversation with the aforementioned few questions can be a good way to get a basic idea about the manufacturer.

Delivery of the Goods

As Universal Manufacturing Corp. reminds, getting the products delivered in a timely manner is an art that must be handled accordingly. For companies that decide to rely on international producers, the entire process becomes even more complicated due to overseas shipping that must take place. How should this stage be approached? A good way to start is to discuss the number of products that will be sent per package. After that, there should be negotiation on how many packages will be needed to meet the monthly quotas of production.

Trial and Error

Unfortunately, even some of the most detailed plans will fail when it comes to the manufacturing and shipping of the products. Things tend to come up and most businesses learn the harsh reality through trial and error. Meaning, companies will often have to go through a few failures before their supply chain is running smoothly. How does one overcome this period? They should first accept the fact that they are not going to be as profitable in the beginning. The reason why is fairly simple, and it boils down to the fact that failed deliveries will be pricey.

After that, they should discuss strategies that will ensure the successful execution of the contract in the future. Although issues may be costly, they are also great for realizing what the weaknesses of the supply chain are. Thus, the buyer should analyze them and come up with ways to have a better relationship with the manufacturer. Ultimately, constantly communicating with the producer will be the easiest way to minimize potential losses.