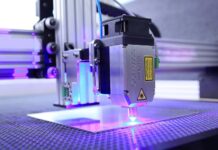

Metal fabrication is a complex domain where precision, durability, and accuracy form the trinity of successful outcomes. Among the many innovations that have revolutionized this field, one invention stands out: the CNC Press Brake Machine. Acting as the backbone of modern fabrication, its role is pivotal, multifaceted, and indispensable. This article dives deep into the world of CNC press brake machines and their profound impact on the metal fabrication industry.

What Are CNC Press Brake Machines?

Computer Numerical Control (CNC) Press Brake Machines are an automated marvel in the field of machining tools. They are fundamentally automated control devices that maneuver other machining instruments like drills, lathes, mills, and grinders, all governed by a sophisticated computer system. The CNC aspect refers to the computer-derived directives that control, monitor, and adjust the operations. In short, a CNC press brake machine is a synergistic combination of mechanical prowess and computerized precision, effectively revolutionizing the way metal fabrication works.

The Role of CNC Press Brake Machines in Metal Fabrication

The application of CNC press brake machines in metal fabrication is extensive and multifaceted. Their functions range from simple bending tasks to complex, multi-step fabrication projects. To understand their contributions, let’s delve into the core areas where these machines make a significant impact.

Precision and Accuracy

Accuracy forms the cornerstone of any metal fabrication project. Any deviation can lead to significant losses in terms of both time and resources. CNC press brake machines offer unparalleled precision. They can follow intricate design specifications with a degree of accuracy that is virtually impossible to achieve manually. The computerized control eliminates human errors, resulting in flawless bends and folds, precise cuts, and a perfect finish every time.

Speed and Efficiency

In a high-demand industry like metal fabrication, time equals money. CNC press brake machines have significantly reduced the time taken to complete projects. They work at a relentless pace, consistently maintaining quality, unlike manual operations where fatigue can lead to reduced efficiency.

Versatility

Versatility is another key aspect where CNC press brake machines shine. They can handle a wide range of materials and thicknesses, bend angles, and complex shapes. This adaptability makes them an invaluable tool for varied fabrication projects.

Reduced Waste and Cost-Efficiency

With their precision and accuracy, CNC press brake machines significantly reduce waste generated from errors or rework. This efficiency results in material savings and ultimately, lower production costs.

Key Features of CNC Press Brake Machines

Understanding the features of CNC press brake machines can provide further insight into their critical role in metal fabrication.

Programmability

One of the most distinguishing features of these machines is their programmability. Once programmed, they can replicate the same operations repeatedly with unerring precision, which is especially beneficial for mass production.

Advanced Safety Measures

Most CNC press brake machines come with advanced safety measures like light curtains and safety sensors. These safety features can prevent accidents, ensuring a safe working environment.

User-Friendly Interface

The user-friendly interface of these machines simplifies the process of setting up the operations. This feature also allows operators to learn and adapt quickly, ensuring efficient handling of the machine.

Durability

Built for heavy-duty use, these machines are known for their durability. Their robust construction enables them to withstand the rigors of the fabrication industry.

The Future of CNC Press Brake Machines in Metal Fabrication

The world of metalworking continues to evolve, and the role of CNC press brake machines is anticipated to grow more prominent. Their potential lies not only in improving the existing processes but also in exploring new frontiers in fabrication techniques.

Advanced Automation

Automation is the driving force of the future, and CNC press brake machines are no exception. With the integration of artificial intelligence and machine learning, these machines are expected to perform increasingly complex tasks independently, raising the bar for precision and efficiency.

Green Manufacturing

As industries worldwide strive for sustainable solutions, CNC press brake machines can play a crucial part in promoting green manufacturing. By optimizing material usage and minimizing waste, they can contribute significantly to eco-friendly fabrication practices.

Customization

The demand for personalized products is on the rise, and CNC press brake machines can cater to this trend by enabling greater flexibility in production. With their programmability, they can produce unique designs efficiently, meeting the growing need for customization.

Skills and Training

With the increasing reliance on CNC press brake machines, the need for skilled operators proficient in CNC programming will also rise. Hence, more comprehensive training programs and educational initiatives focused on CNC machinery are expected to emerge.

Realizing the Potential of CNC Press Brake Machines in Metal Fabrication

Harnessing the full potential of CNC press brake machines involves understanding their capabilities and integrating them effectively into the fabrication process. Here are some key considerations:

Selecting the Right Machine

Choosing the right CNC press brake machine involves considering factors such as the type of work, material specifications, and production volume. A machine that aligns with these requirements can enhance productivity and result in better quality outcomes.

Regular Maintenance

Regular maintenance of the machine ensures optimal performance and longevity. Routine checks can prevent potential breakdowns, reducing downtime and maintaining a consistent output.

Skilled Workforce

Even with automation, the role of skilled operators cannot be undermined. Training the workforce to proficiently handle these machines can boost efficiency and productivity.

Embracing Technological Advancements

Staying abreast of the latest technological advancements and incorporating them into the CNC press brake machines can yield better results. This could involve upgrading the software or adding new features that enhance functionality.

Conclusion

In conclusion, CNC press brake machines have significantly influenced the metal fabrication industry’s trajectory, elevating it to new heights of precision, efficiency, and versatility. As we look towards the future, their role is likely to evolve, carving a path for advanced automation, sustainable practices, and personalized production. It is imperative for businesses to fully harness their potential and adapt to these changes to thrive in this dynamic industry. With the right selection, regular maintenance, skilled workforce, and an eye on the latest technology, CNC press brake machines can indeed prove to be the lynchpin of a successful metal fabrication venture.

Find a Home-Based Business to Start-Up >>> Hundreds of Business Listings.