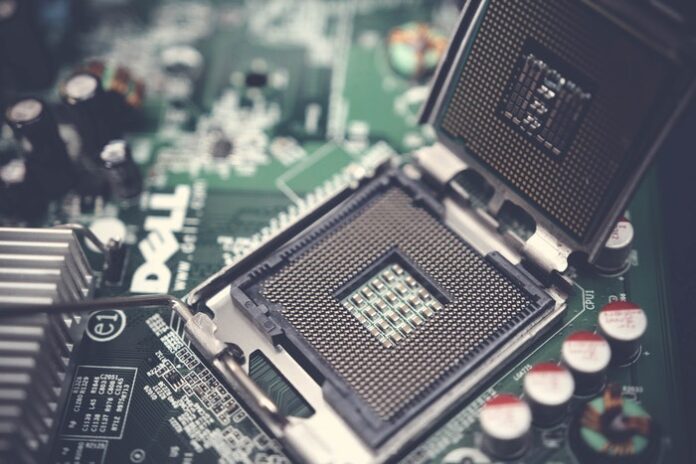

The world is running out of chips and there are few things that affect production lines more than a chip shortage because chips are an absolute essential part of all our communication products, appliances, gadgets, automobile and tech products. From your PC’s microchip to the most complicated ones that control aircraft, chips are ubiquitous across all fields of work. This is why some companies have had to halt production, delayed product launches as Samsung did for Galaxy S21 FE.

Nobody has taken this into account before the COVID-19 triggered-crisis that chips are among the most vital nonnatural resource for the developing world. They are the foundation of every innovation, powering every iPhone and Android device. They’re also at the heart of any computer, smart device or machine that we interact with on a daily basis. So, it’s only natural that there’s a demand for more and more chips to power the trend toward smart gadgets and more efficient devices. But it’s becoming increasingly difficult for chip manufacturers to keep up with this growing demand once the production was affected by COVID-19, drought in Taiwan and some other reasons.

Why is it difficult to control the crisis immediately?

According to the supply and demand principle, a shortage can’t be overcome until there is a supply surplus, which is not going to happen in the case of chips anytime soon. The world’s leading consulting firm Deloitte in its Technology, Media & Telecommunications 2022 Prediction Report has predicted that the chip shortage won’t be over during the whole of 2022 and companies will still be waiting 10 to 20 weeks at the end of the year.

Deloitte is also seeing a whooping growth of investment in the chip production industry and estimates that venture capital firms will be investing $6 billion in various chip-producing companies in 2022. But despite huge investments, there’s no short-term solution to shortage. Industries need to find suppliers who already have various chips in huge quantities to meet the demand of industries.

Online suppliers of electronic components in Asia can be the immediate solution to this problem because these sellers have direct links with the chip-producing companies and have millions of chips in stock.

But only those suppliers can be trusted who are in the industry for some time and have an after sales support network.

Find a Home-Based Business to Start-Up >>> Hundreds of Business Listings.