When you’re running a factory, you need to think about how to keep it running at the optimum level. If you can accomplish this, then you will achieve great success and keep the factory as productive as possible.

Do You Have Enough Space?

Space is one of the big things when it comes to running a business. You have to make sure you have enough space that everything can be completed in the best possible way. The different areas of the factory production line need space to thrive and grow. The last thing you want is for everyone to be on top of one another. And that’s why you have to make sure there is enough space in the factory. You may have to rearrange things, or think about how you can extend to increase and maximize space. Vape Craft, a company that makes eliquid, doesn’t need a big factory, but needs to have a clean factory to comply with industry standards.

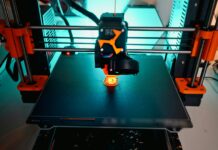

Check You Have the Right Machinery

The most important part of any factory is the machinery because this is how the manufacturing is done. So you have to think hard about whether you have the right machinery to be able to run as well as you can. Take a look at the different machines and equipment you need to run your factory. Check out the best plasma cutter and the most effective injection moulding you can find. These are going to be essential parts of factory production. So you have to make sure you have all the necessary machinery and equipment to help you run as well as you can.

Increase Your Targets

If you want your factory to grow and become more productive you have to look at what your targets are. Reaching the optimum level for your factory is important, and this is all about targets. You don’t want to set targets that are too high that you have to spread your resources thin. But, at the same time, you also don’t want to be in a position where you’re selling yourself short. Try to increase your targets, so you’re more productive each day, but try to do it so that you are still operating as effectively as possible. This is the secret to success and the way to make your factory thrive.

Hire More Workers

You may get to a point where you feel like you don’t have enough workers in your factory. And in this instance, you need to make sure you hire more. You may want to expand and grow the factory, and start to take on more jobs. And, as such, you will need to make sure you have the right number of workers. This is important for helping to make the factory efficient and productive, and ensure it operates at the highest level. But, it’s also important for health and safety because you need to have enough people to ensure that certain areas are safe.

Running a factory is not as easy as you might think it is. You need to make sure that everything is perfect and that all areas operate as well as they can. The factory plays a larger role in the business because it’s where products are manufactured and produced. So it’s important to ensure that it’s running at the optimum level at all times.

Find a Home-Based Business to Start-Up >>> Hundreds of Business Listings.