Walking down the food aisles in a neighborhood grocery store or at Walmart, we are certain to find innumerable food items stacked on shelves. Be it our staple food requirements or the indulgences of cookies or chocolate, we are spoiled by choice. The variety of packaged and quick food fixes at our disposal is unimaginable. With new tools, things have gotten a lot easier too. For instance, did you know that you can browse air blowers any time you want? You can visit Hot Air tools to know more.

According to a report generated by Statistica, the U.S. food retail industry amounted to $318.48 billion in 2018. On average, buyers made 1.6 grocery store visits per week in 2018. Moreover, the U.S. fast food industry is currently estimated at $198.9 billion and is likely to cross $223 billion by 2020. The U.S. alone boasts of 232,611 fast food outlets within the country. These brands are not just limited to the boundaries of the nation but have also gained global recognition.

The global scenario is no different when it comes to revenue generated by the food industry. The worldwide sale of packaged food in 2019 is forecasted at $2.64 trillion. Substantial revenue goes into digital advertising and marketing of these revenue generators, standing at $23.5 billion in the U.S in 2018.

Quick and Easy

The food industry has an extremely quick turnaround time, implying that the production has to be bulk, quick and streamlined to meet the market demand. In an era of instant messenger, the food industry has to comply and keep up with the public demand. Instant noodles, ready-to-eat food mixes, and restaurant drive-throughs are testaments to these Gen Z needs. It is a fascinating process of how these food items find their way from agricultural fields through factories and stores then onto your kitchen counters.

It requires a lot more than the physical effort to turn raw materials into consumable finished products, and this has been made possible through the advances of technology, research, and development.

The Process of Food Production in Factories

Fetching Raw Materials

The primary step in the production of food is procuring the necessary raw materials required to prepare the end product. It is important to control the pricing and make necessary quality checks to make sure what goes into the making of the food item is of the utmost quality.

Grading and Washing

At this step, any low-quality ingredients are separated from the good quality and cleaned before mixing all the ingredients together. Different processes such as filtration and sterilization are conducted under controlled temperatures.

Processing

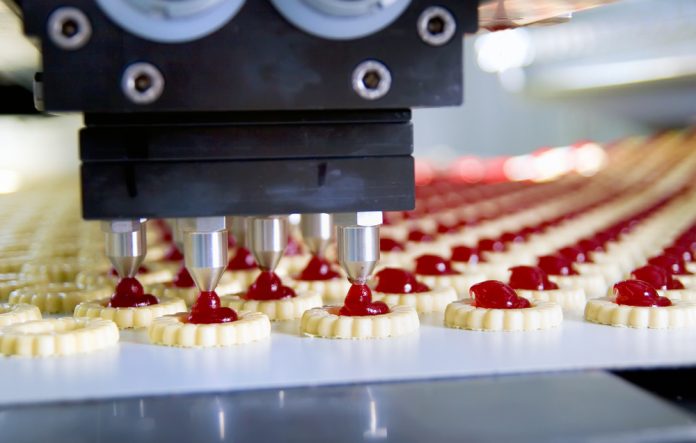

The main action takes place here where the final product begins to take shape. All the raw ingredients are combined together in correct measures, processed through cutting, grinding, cooking, baking, boiling, etc. Additional flavorings, emulsifiers, and preservatives are added, and the food is molded into the desired shapes. The food is controlled under the right temperatures, heated or cooled as required to avoid spoilage.

Packaging

Product packaging determines the quality of the food item, protecting it from the external environment and preserving the contents inside the package. Major investments are made in the quality of the packaging material used, its design, durability, ease of transportation and if it will visually attract the buyer. Several processes occur simultaneously at this stage.

Special measures and precision is required to ensure the packaging is not faulty, the food is compressed or sealed under the right atmospheric pressure (often through Vacuum packaging) and there is no exposure of the contents to the external environment. Any kind of labeling on the package is done during this stage.

Quality Control

Quality checks are made at each stage of the production process to ensure the best food reaches the customers.

Transportation

The final product makes its way from the disciplined assembly chain in the factory to the hustle and bustle of the wholesale and retail market for final consumer consumption.

Ever wonder how our favorite snacky, gooey gummy bears that manage to tempt us by the mere sight of them reach our hands?

- These candies are mass produced in the thousands by first mixing corn syrup, gelatin, sugar, water, food coloring and flavorings in the form of citric acid or fruit juices.

- These ingredients are cooked together until a thick liquid forms, which is called slurry.

- Molds for the candies are prepared by lining them with corn starch to avoid sticking, and then the slurry is poured into these molds for shaping.

- These molds are cooled and set for 24-26 hours under a temperature of 65 degrees Fahrenheit.

- After the gummy bears are well set, they are removed from their molds into a large tumbler filled with food-grade oil to absorb excess corn starch and give the candies their desired texture and retain freshness.

- Finally, the delectable candies are packed and transported to stores for sale.

Find a Home-Based Business to Start-Up >>> Hundreds of Business Listings.