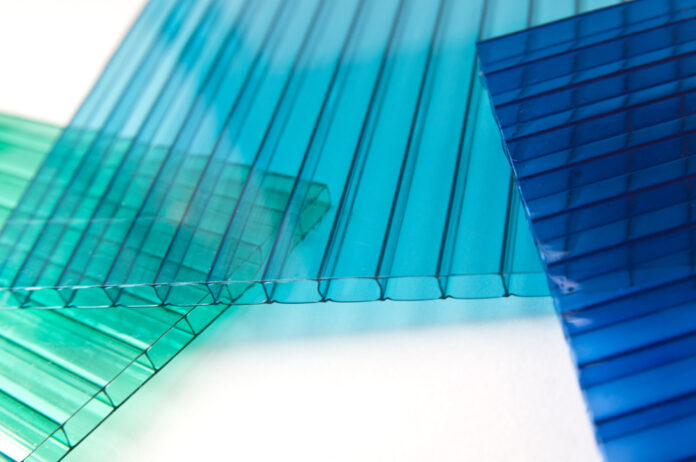

For over 40 years, multiwall polycarbonate sheets consistently have risen in the marketplace to be used for a variety of things, mainly cladding, roofing, skylights, sheds, greenhouses, and verandas. Most industrial buildings are now constructed with this multi-purpose material, which provides a plethora of advantages in terms of high environmental quality. Perfect insulation qualities, durability, and high impact resistance are just a few of the benefits.

Multiwall polycarbonate sheets provide equivalent insulation to glass at significantly lower prices. They have excellent intrinsic insulation properties, which aid in keeping heat in the structure. Further anti-heat treatment can increase this functionality by optimizing energy management in the property during cold months, reducing loss of heat. It can also help prevent heat inputs in the warmer seasons. The thermal insulation coefficient of multiwall polycarbonate can be as low as 1 W/m2 K with simple panels and even lower when panels are combined in double-skin systems and if that was not advantageous enough, the prices are unbelievably low. When it comes to multiwall sheets, SABIC is one of the prominent names in the industry.

Optimized Integration for Architectural Projects

What makes multiwall polycarbonate sheets even better is the optimized integration for all architectural projects. Multiwall polycarbonate panels are popular because they can be customized in an extensive variety of colors, finishes, and types, such as frosted, opal, or translucent. They can be smoothly implemented into the structure of an industrial building or utilized as decoration in the interior design. Furthermore, their cold bending aspect allows the panels to fit various particular requirements. This aspect allows for the creation of a specific form, which benefits architectural design.

Eco-Friendly Material

Since the panels can be cut to the desired length during the manufacturing process, waste from offcuts produced during on-site installation of multiwall polycarbonate sheets is significantly reduced. Furthermore, multiwall polycarbonate panels can be made not only from a virgin but also from recycled material. However, the recycled material must be derived entirely from post-industrial waste. Polycarbonate, due to its inherent properties, is a sustainable material with a low environmental impact. At the end of its life, it is completely recyclable. This is beneficial for companies that wish to be as green as possible and have a good reputation in the industry.

Cleaning and Maintaining Multiwall Polycarbonate Plastic

Avoid using abrasive or high-alkaline cleaners on multiwall polycarbonate sheets to retain integrity for as long as possible. Do not let cleaners sit on multiwall polycarbonate sheets for long time periods, and rinse promptly with cold, clean water. Applying cleaners in direct sunlight is not recommended; avoid using squeegees, sharp objects, or razors.

Features and Benefits of Multiwall Polycarbonate Plastic

Multiwall polycarbonate sheets are virtually unbreakable; they are ten times stronger than plexiglass and over 200 times stronger than glass. Despite their extreme strength, multiwall polycarbonate sheets can be cold-formed on-site without splitting or cracking. Since they are so versatile, they are commonly used for residential flat and curved glazing, roof glazing, building facades, claddings, greenhouse roofing, skylights, and walkways.