Electromagnetic interference, or EMI shielding solutions, can actually affect the operation of electronic devices. Techniques to protect the circuits against unwanted signals are called Shielding. Effective EMI protection is essential for ensuring that your devices perform as designed, reliably, and safely. Here are eleven viable protection methods for electronics.

1. Conductive Gaskets

Gaskets are conductive components that create a seal between enclosure parts, blocking electromagnetic waves from passing through the gaps. These gaskets more frequently employ silver-coated fabric or conductive elastomers. Their pliability allows them to be shaped around enclosure contours, providing continuous protection across enclosure joints and seams. It is worth noting exactly how EMI shielding solutions for electronic devices combine multiple conductive layers to achieve both shielding and absorption requirements.

2. Shielding Foil

Copper or aluminum metal foils form an excellent barrier to interference. When these features are applied to the surfaces of circuit boards or equipment enclosures, the foils are used to reflect and absorb EMI or EMC as undesirable energy. Because they have a thin profile, they can be appreciated in compact assemblies without much bulk.

3. Shielding Paints

Metal particle-filled special paints are used as internal coatings for enclosures. After drying, these coatings provide a conductive blocking layer that prevents external signals. They offer a low-cost option for retrofitting legacy housings, requiring no new hardware or complex installations.

4. Metal Enclosures

Metal enclosures, typically made of steel or aluminum, offer some of the most robust protection due to their solid metal construction. The green continuous working surface on which they perform block incoming and outgoing interference. These cases are ideal for equipment that requires stringent shielding specifications, such as medical or aerospace devices.

5. Fingerstock

Fingerstock is simply a thin slice of metal, typically made of beryllium copper, that provides electrical contact between enclosure panels. These strips form a continuous path for the unwanted signal on compression. These come in handy for removable covers or doors that require frequent access.

6. Shielded Vents

Cooling is often required inside electronic devices, but for heat to escape, such openings offer a path for interference to ingress. Protected vents use either mesh or honeycomb types of conductive patterns to allow air to pass, but block unwanted signals. These ventilation spaces provide a useful compromise between cooling and the retention of electromagnetic protection.

7. Ferrite Beads and Cores

Ferrite beads and cores are used to suppress common-mode noise that propagates on cables or circuit traces. It prevents undesirable energy from entering or leaving a device by absorbing high-frequency signals. They are easy to install, which makes them common in power and signal lines.

8. Conductive Tapes

Metal-coated adhesive tapes (e.g., copper or aluminum) that are easy to handle and apply as shields. These tapes are useful for sealing enclosure seams, wrapping cables, or covering components that are still fairly sensitive. They are ideal for quick repairs or temporary shielding, due to their flexibility and convenience.

9. EMI Shielded Windows

Shielding is less effective if a display or sensor needs to be protected. Shielded windows are different; they actually have a conductive mesh or coating on the glass (or plastic). This design is intended to prevent any electromagnetic energy from reaching screens and view planes that are sensitive to EM energy, while allowing visibility through the construction.

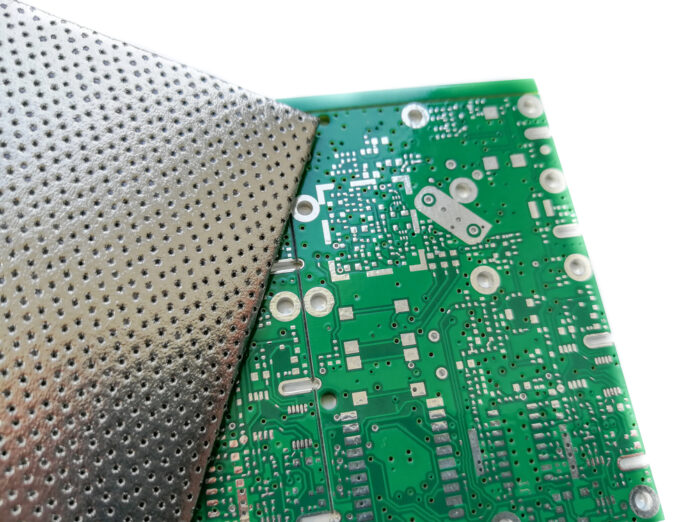

10. PCB Shielding Cans

Metal cans often protect sensitive sections of printed circuit boards. These covers protect components from external sources of disturbance. Removable versions of it help in accessing the full component easily during maintenance or testing while offering both protection and convenience.

11. Absorptive Materials

Other solutions utilize materials that do not reflect electromagnetic energy but instead absorb it. Interference is also trapped inside foams or sheets that are impregnated with carbon or metal particles. Such materials are installed in enclosures or used in cable applications to minimize emissions and vulnerability.

Conclusion

Effective EMI shielding solutions is essential to ensure the reliability and safety of electronic devices. Depending on the device’s design and the environment in which it is used, each solution offers its own set of benefits. There are multiple options available to engineers, ranging from simple tapes to high-end, robust metal enclosures. By understanding these methods, we can better protect our application and enhance its performance.

Find a Home-Based Business to Start-Up >>> Hundreds of Business Listings.