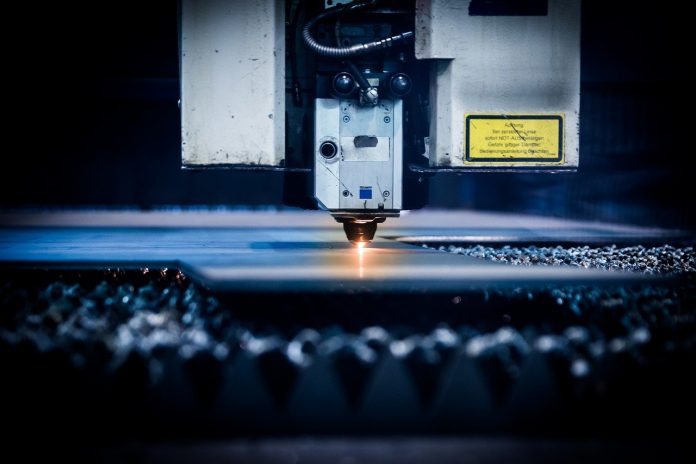

Laser cutting is a neat process to watch. Basically, it’s a fabrication process that uses thin laser beams to cut and engrave all sorts of materials, from fabric to gemstones and everything in between. Design software is used to create a project, which connects to the laser cutting machine to tell it what to do. There are different types of different types of DIY laser machines that can be used for industrial applications, home-based businesses and even hobbyists. Prices range from around $600 for small machines with limited capabilities, such as engraving, to $30,000 or more for industrial grade machines suitable for manufacturing. Here we’ll take a look at two levels of laser cutting machines that are more on the industrial end of the spectrum.

Entry Level Laser Cutting Machines

Costing an average of $4,000, entry level laser cutting machines are still professional grade machines, but designed to a smaller scale with the needs of hobbyists and small businesses in mind. These machines are capable of laser cutting wood, acrylic, leather, fabric, foam, fiberglass and a variety of other materials. Computer design software is typically included, along with support such as video tutorials for getting started and for troubleshooting problems during operation. Some models also include extra features, such as knife blade platforms, which allow users to create projects with engraving.

Industrial Level Laser Cutting Machines

Designed for industrial applications with more stringent needs, such as the ability to cut thicker materials, this grade of laser cutters costs around $10,000. Also equipped with computer design software, these larger machines are often used by industries such as electronics, aerospace, automotive and even medicine. More commonly known applications for this level of cutter include metal business signs, personalized gifts or corporate novelties. And recently, Industrial Laser Solutions reported that many companies that use laser cutting in their operations have switched portions of these operations to producing PPE equipment in response to COVID-19 shortages. Face masks are a common example of PPE these companies are helping produce.

Access to Laser Cutting Machines

Not all hobbyists or even small businesses can afford laser cutting machines out of pocket and don’t feel confident in the idea of financing one. Fortunately, access can be found in many Makerspaces across the country, as the Makerspace movement grows. According to the Urban Libraries Council, a Makerspace is a community shared space for making, sharing and learning. Set up with equipment such as sewing machines, 3D printers, and laser cutters, as well as non-tech equipment and supplies, Makerspaces are most often found in libraries and schools. There are also community-owned Makerspaces, sponsored by city councils and private businesses. One of the key ideas behind the movement is providing access to tech that is not affordable for most members of a given community. Small business owners and hobbyists interested in selling the things they make can take advantage of laser cutters through local sharing spaces like these.

Interest in the capabilities of laser cutting machines has grown in the last few years, especially among those in the private sector. As this interest continues to grow, as it is bound to, consumer demand for home use laser cutting machines will grow as well. Much like Cricuts and Carveys, laser cutting machines for home use aren’t far off, and are likely to be just as popular as other home use tech.

Find a Home-Based Business to Start-Up >>> Hundreds of Business Listings.