Ball screws are used for increasing machinery efficiency and with their variety in sizing and capabilities, they can be a match to most given mechanical applications. Use the appropriate ball screw for the machine and consider things such as accuracy and lubrication to determine what the best specifications are for the purpose.

Several myths exist when it comes to ball screws and their functionality. These misconceptions can guide one away from this useful low friction mechanism. There are no perfect machines, and ball screws are no exception. For the issues that do exist, there are simple solutions that are commonly overlooked which can be implemented to ensure use is successful when using them.

What Are Ball Screws?

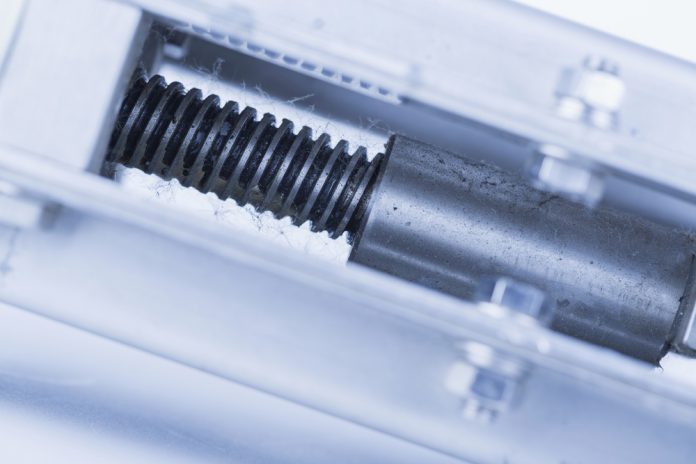

Ball screws are mechanical parts produced to ensure improved efficiency in machinery. Their sizes and strengths vary depending on what purpose they are being used for.

The technical way a ball screw works is that as it begins to rotate, it uses small recirculating ball bearings which will work towards decreasing the amount of friction. Since friction is an unavoidable factor in the efficiency of screwing any part together, the less resistance there is, the easier it will be to operate.

Myth: Backlash Cannot Be Minimalized

What It Is

The term backlash refers to a loss in motion in a mechanical device. Backlash basically amounts to wasted energy. This is caused, even with ball screws, when gaps form between the screw and ball bearings within the nut, allowing the outer part to spin without the whole device moving. A reversal of the direction of motion is noticeable when this occurs. This motion of resistance is definitely noticeable, but there are solutions that can cut down on this slight problem during use.

The most common problem associated with ball screws is this. Test studies and technological advancements are occurring to enhance ball screws to be able to have lower reports of backlash.

How to Solve It

The best solution to this issue is using a ball screw with an adjustable preload. This type of ball screw uses springs to adjust how tightly the nut and screw tracks are pressed against one another. A ball screw with an adjustable preload will form fit to the minor differences between screws of the same size.

Other methods to eliminating backlash from ball screws exist, but the simplest method is directly contacting the supplier. Certain ball sizes are better suited to perform with little backlash and can be ordered from the factory.

Myth: Low Travel Accuracy Because of Size

Exploring the Myth

Travel accuracy is determined by how efficiently a screw can be driven, down to the exact degree. This is important in devices that small margins for error allow it to run smoothly. The better the travel accuracy, the more energy-efficient the device is. Since ball screws are known for being large, it is common to hear their travel accuracy suffers because of their girth.

How to Solve It

Educate yourself on the accuracy of ball screws and how different types will vary in precision. Learning the basics of ball screws will lead you to understanding many of the connotations that surround them that are not true. A traveling accuracy for a ball screw will not be affected by the size if it is purchased accordingly. Ordering a custom-sized ball could relieve any added friction from parts become too close together.

Myth: Double-Nut Is the Best Method

Exploring the Myth

The double nut method is an older technique that is still widely used today. As technology progresses, it takes time for older less-efficient methods to fade out if they are well known. While relying on long-standing methods may be easier on the user, it is a less practical option for a smoothly running mechanism in need of advancement.

Many believe the double-nut method will double load capacity because there are two nuts that can take the weight smoothly, but that is simply untrue. Only one nut will take the load at a time. Not only that, but each nut only takes the load in one direction.

How to Solve It

A ball screw gets the same job done at a cheaper price and they are easier to deal with. The ball bearings in a ball screw take each ridge in the nut load bearing in both directions. Ball screws can come fitted to the consumer’s specifications, allowing for improved smooth movement. This is most noticeable in precision ground ball screws that are known for their advanced accuracy.

Myth: Premature Breakdown from Lack of Lubrication

What It Is

Maintenance is not needed when dealing with the lubrication of ball screws since most are guaranteed to last for life. When a ball screw fails the most common explanation is lubrication. This is still the leading cause of why ball screws will experience failure before their lifespan is due to end.

One of the explanations point to the way they are tested. They are laid out in a clean lab environment while bearing no load. Ball screws in the real world do not perform in those same conditions. These scientific studies on a ball screw’s lubrication and accuracy cannot pinpoint other contributing factors to malfunctions in the field.

How to Solve It

Understand that many problems can occur within any device, and ball screws are subject to the mechanisms’ capabilities of working cohesively. It is true that ball screw lubrication does not last its lifetime, but it lasts longer than in most similar devices. Often the reason lubrication is the fault of a ball screw’s failure is because of the durability of its other long-lasting parts.

Use Ball Screws Correctly

Ball screws have been increasing in popularity since their conception, thus causing more advancements and faulty in-between products producing some bad misconceptions. Many of the myths associated with ball-screws are from misuse and not understanding the ways to improve and work with your particular ball-screw for optimal precision. Ball screws can be used efficiency with a little research and even some custom ordering.

Find a Home-Based Business to Start-Up >>> Hundreds of Business Listings.