The manufacturing industry is on an upswing. Increased customer demands mean that the metal stamping industry, which is at the core of many manufacturing processes, will have increased demands placed on it. How can the manufacturing operations be optimized? What role does proper metal stamping tooling play? Before we consider these questions, let us first understand the operation.

What is metal stamping tooling?

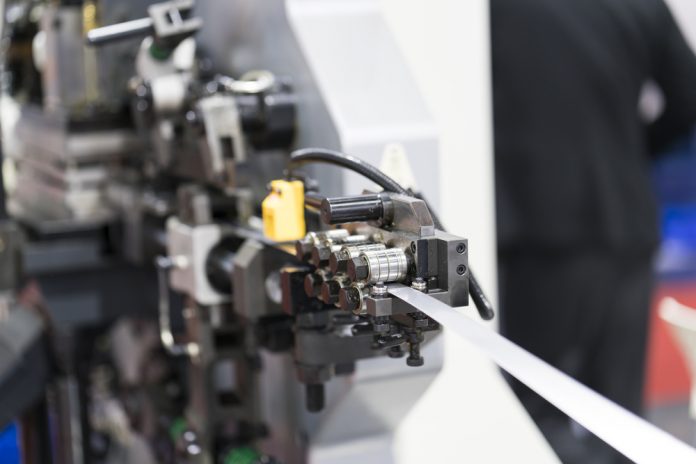

Metal stamping is the process through which a metal sheet or a coil is cut, shaped, or formed in other ways to provide the desired product. A skilled workman is only as good as the tools he possesses. Metal stamping tooling is what enables a skilled craftsman to produce items ranging from simple objects like a paper clip to complex aeronautical parts from sheet metal.

A press provides the force needed to carry out the operation on the metal sheet. Although generally the word die refers to the entire metal stamping tooling, it actually is only the female half of the tool-set. The male half is called the punch. Thus the punch and the die work in opposition to each other. They are mounted on the upper and lower assembly of the press and guide pins in matched or ball bearing bushings ensure that they are properly aligned with each other.

Sometimes multiple operations are carried out on a single die station or they are carried out on multiple stations with a single stroke. In such single station operations, a compound or a combination die is used. A compound die is used basically for cutting operations while combination dies are used for cutting operations combined with shaping and forming. At times multiple stations are required to complete all the processes. They perform a series of operations simultaneously. A progressive die process is when the item is manufactured from coils and remains connected to the coil during the different operations. It is cut out and separated from the coil only in the final operation. A carrier strip ensures that it remains in place and moves along for progressive operations to be carried out. In the transfer process, the parts are cut out of the coil at the beginning of the process and mechanical arms or transfer devices carry it from station to station for the different operations that are involved.

Optimizing manufacturing operations for metal stamping tooling

Optimizing your manufacturing operations is necessary to balance your costs with the revenue generated or the return of investment. This would require that careful thought is given to tool design, material selection, machining, and maintenance.

Consider six keys that would help you optimize your manufacturing process to ensure maximum returns.

- Automation: In recent times, automation has made great strides. While automation costs quite a bit depending on how complex the process is, it improves accuracy and consistency. It also increases production since machines obviously work faster and longer than humans can.

- Training: No matter how good the tools you have, how well they function would depend on how well-trained your operator is. Although you may have an automated process, the human element is still crucial, since any machine, and any process requires maintenance. Constant monitoring is important to ensure quality and prevent breakdowns that could result in costly downtime. Ensure that your operators have a good knowledge of the materials being used, the functioning of the equipment, and the way the final products would be eventually used. This will ensure that they are in a position to optimize your manufacturing operations. Regular proactive sessions with well-trained operators could provide you with insights that could prove very helpful.

- Minimize transitions: At times the process would require that the material is moved from one machine to another. This is time-consuming. Give thought to the layout of your factory floor. Could the equipment be positioned such that machines serving consecutive processes are next to each other? This would save time and you could then even consider a link that could take the item through to the second machine without human intervention.

- Cut down on losses: One thing that often cuts into production is small stops that then require setup or adjustments and results in startup rejects. Plan your workforce and their schedule such that the machine can run continuously without needless stops.

- Regular maintenance: There is a direct link between profitability and downtime. Every piece of equipment requires regular maintenance. Ensure that preventive maintenance is a part of your operator’s regular schedule. Even where there is a problem, a well-trained operator should know how to troubleshoot.

- Good organization: A well-organized process enhances productivity. But an organized workspace is often not given the importance it deserves. Organizing the tools and materials logically goes a long way toward optimizing the manufacturing process.

Optimizing your manufacturing operations will help you thrive in the competitive market of today. It will help you ensure that you are able to not just meet the industry demands but do so in a profitable manner.

Find a Home-Based Business to Start-Up >>> Hundreds of Business Listings.