We’d argue digital light processing (DLP) is the reason rapid prototyping is revolutionizing so rapidly (play on the word intended).

And rapid prototyping and how advanced it’s becoming is why we’re now seeing more precise 3D CAD data than we have ever seen, which is directly benefiting industries like manufacturing, engineering, etc.

How is DLP revolutionizing the rapid prototyping process? Read on to find out.

How Rapid Prototyping Has Evolved

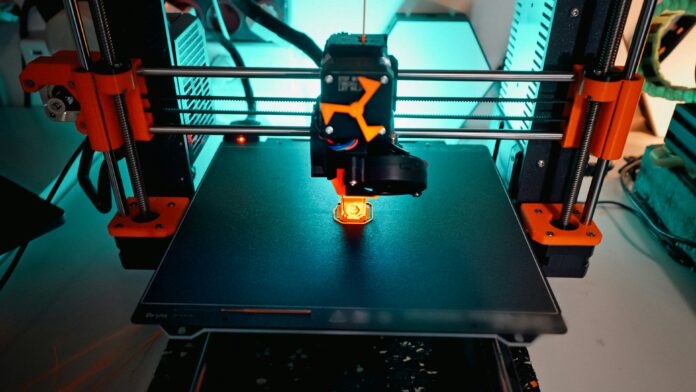

In the past, rapid prototyping meant a very slow, unrefined, and somewhat horrid lump of a print. Literally the opposite of the name. You would wait hours for something that looked like it came from a fire, and you would painstakingly have to try to make it work.

Then, machines became faster, filaments improved, and resins became stronger. Suddenly, your prototype resembled your product and you could hold it.

Software improved too. Designers were finally able to push the boundaries that the technology permitted. Need complex geometry? Rapid prototyping. Organic curves? Rapid prototyping. Interlocking components? Of course, rapid prototyping.

What once took weeks is now finished in hours. What used to cost thousands of dollars is now a few hundred.

All this evolution served as a foundation. But DLP? That is the leap.

Why DLP 3D Printing is the Revolution Rapid Prototyping Needed

DLP printing arrived with a bang. It fully opened the door and announced that rapid prototyping is ready to actually become rapid.

DLP cures a complete layer with a digital light projector, so when compared to other 3D printing methods that need layer-by-layer construction, it offers insane speed. And we don’t just mean fast. We mean unbelievably fast.

But speed is just one thing that one of its types offers. DLP also boasts surface quality like you’ve never seen before. You get sharp edges, polished surfaces, and precision accuracy down to microns.

For prototyping, that is significant. Be it pitching to the investors or testing a component, your prototype should appear as though it is already in the production stage.

The Potential of Rapid Prototyping

This is where it gets really interesting. We are no longer dealing with prototypes that are only for outward appearance. We are creating prototypes that serve a purpose, prototypes that can gather feedback and need pre-production batches.

It facilitates quicker decision-making and it accelerates product development cycles. The product surprises the market with fewer unanticipated issues.

Aerospace instruments, surgical guides, engine components, or parts that need to be changed quickly where development speed saves money and lives.

Even the small fish can swim in the same pond as the big players. A DLP printer easily joins the list of devices required for modern innovation together with a good idea and a decent CAD file. From being a stepping stone, the goal of rapid prototyping has transformed into a strategy.

DLP technology has improved prototyping by redefining it. Rapid, clean, and accessible prototyping is here. Where speed wins and precision rules, having access to DLP technology is everything.

Find a Home-Based Business to Start-Up >>> Hundreds of Business Listings.