Typically, the headlines about the industrial developments focus on AI-powered machinery, sci-fi-like wireless technology, or breakthroughs in chemical processes. Meanwhile, the wires and tubes that keep those systems alive are rarely remembered. They, too, are undergoing groundbreaking advancements.

The new industrial landscape requires flexibility, efficiency, adaptation to tight spaces, and, above all else, resilience. Here’s how the next generation of flexible tubing is connecting today’s industries to the future.

A Solid Case For Flexibility

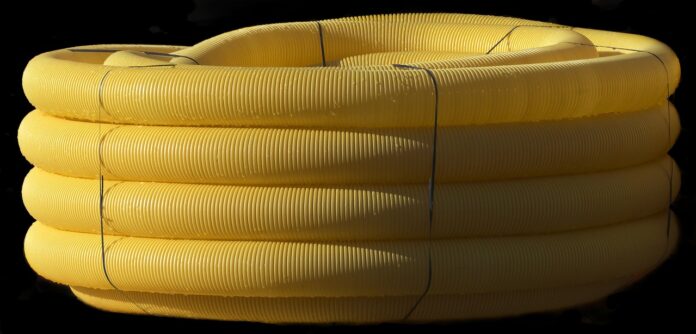

Indeed, polyurethane rubber tubing is much superior to the traditional rigid pipelines. For starters, these tubes absorb impact much more efficiently. Also, they aren’t affected by machine vibrations. Under stress, rigid pipelines can simply break, compromising the entire operation.

Besides, rigid pipes have fixed structures. So, it can be quite troublesome to move them around the premises, if necessary. In contrast, industrial flexible tubes can go around corners and are much easier to remove. It’s a tremendous advantage when it’s required to move them to a new location. Modern tubing uses advanced protection with materials highly resistant to corrosion. From harsh environmental conditions to chemical exposure, these tubes are ready.

Unsurprisingly, the global market for industrial flexible tubing is set to grow at a CAGR of 4% up to 2030. After all, highly resistant flexible tubes are vital for a range of industries, going from healthcare to aerospace. Specific demands regarding materials and resilience capacity may vary across different industries. Yet the need for versatile, cheap tubing is shared across the board.

Where Flexible Tubes Makes the Difference

It’s hard to imagine an industry that doesn’t use flexible tubes at some point in its processes. However, some branches simply couldn’t exist without them. In the age of Industry 5.0, where smart equipment is the star of the show, flexible tubes remain vital for food and beverage production, chemical processes, automotive, agriculture, renewable energy, and, of course, plumbing.

Apart from their superior versatility and durability, rubber tubes are also cheaper and much easier to maintain. Indeed, these industries are very picky about flexible tubing, and rightly so. Malfunctioning pipes inside a car engine could cause a deadly accident. The same goes for aerospace, and planes could simply explode mid-air. Similar problems in food and agriculture can lead to contamination, risking everybody’s health.

Malfunctions are not an option. That’s why these sectors rely only on rigorously tested solutions that comply with international quality and safety standards. With decades of expertise in manufacturing and supplying high-performance tubing, Italian manufacturers have become trusted partners across multiple fields. Over the years, leading brands in the pharmaceutical, medical, and automotive sectors have relied on their products and services, building long-term, value-driven collaborations.

The Vital Link

While flashy technologies dominate the headlines, flexible tubes remain the unsung heroes of the most advanced industries. Just like complex machinery, these tubes haven’t stopped in time, evolving continuously to become more resilient, adaptable, and efficient. As it turns out, industrial progress doesn’t depend solely on semiconductors and digital technologies such as AI and machine learning.

Find a Home-Based Business to Start-Up >>> Hundreds of Business Listings.