Laser Precision Solutions or LPS is a company that designs laser products for industrial and commercial purposes. Their designs must be reliable, precise and in the right budget parameters for their clients. Producing the LaserTrain has been a boon for LPS, but it hasn’t been without its challenges. Take a close look at this case study and how LPS was able to cut their manufacturing costs by 50 percent with the help of 3D Hubs.

1. Proposing the Challenge

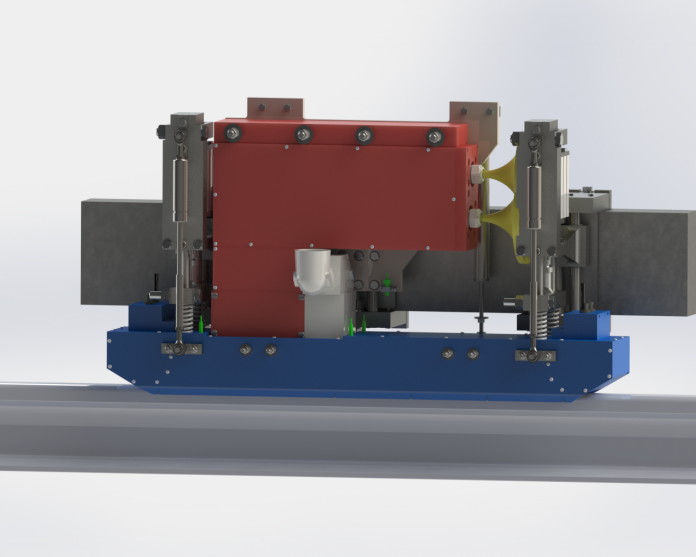

The LaserTrain is a device that attaches under a locomotive where the wheels meet the railhead. Its job is to apply a laser light that effectively cleans contaminants off the metal. A safer and more efficient train ride is achieved as a result.

LPS is the only company that offers this technology, and the LaserTrain’s first generation of devices are in their second year of service in New York state. The production challenge arose when LPS was ready to update the device while expanding its numbers on the Eastern Seaboard.

2. Sorting Through Traditional Production Pathways

LPS could always work with its original suppliers for a CNC quote, but they faced limits to the budget. The suppliers were numerous with too many quotes to keep straight. Adding up the costs was an accounting challenge. It was just too expensive to update and produce the LaserTrain through traditional pathways.

3. Understanding the Materials Involved

Another challenge was the materials involved. LPS needed a production facility that could handle these materials on a regular basis, including:

- Aluminum

- Glass

- Rubber

- Plastic

- Heavy-duty steel

- Aircraft-grade aluminum

Most production facilities had limitations on materials, which gave LPS the impression that they had to break up their manufacturing line. Production costs were sure to rise with this scenario in play.

4. Seeing the Parts in Action

All of these challenges made it difficult for LPS engineers to see their creations in real life. They relied on computer simulations and scaled-down models. A few instances offered real prototypes, but they were never of the highest quality.

Engineers needed to see the LaserTrain’s parts in action before mass production. Their choices were limited until they discovered 3D Hubs.

5. Discovering 3D Hubs

3D Hubs is unlike any other production facility in the world. This company uses the power of the Internet to give engineers a chance to upload their designs. They also request specific materials for each item.

The system goes into action at that point. After passing the Design for Manufacturing or DFM checkpoint, the system allocates the design to the proper location for production. It doesn’t matter where the design comes from. Its manufacturing process can occur in one of 140 locations that’s associated with 3D Hubs. The exact materials are always used for the prototype or production order. They ship out with expeditious speed.

6. Revealing Engineering Concerns

LPS saved money on production costs with this instant upload from any Internet-connected computer. They also achieved more cost savings by having the DfM checkpoint as part of the upload process. In fact, three errors were found before the design even hit the production floor.

The errors were corrected as the engineers learned more about alternatives to their designs so that materials and time were saved. The final parts weren’t compromised in quality at any point. The system simply found a way to simplify the design with its specifications as guidelines.

7. Watching Costs Drop

LPS needed these parts to be made in bulk so that they could supply their clients in New York and beyond. With design defects solved and material volumes optimized, the cost of each LaserTrain dropped dramatically. Any future updates to the device could easily move through this same process again. The DfM checkpoint can move through the design as if it’s brand new once again. In some cases, running an update through the system might drop the prices again. Streamlining production is possible with computer verification and subtractive manufacturing online with 3D Hubs.

8. Achieving Short Lead Times

Along with cutting their costs by 50 percent, LPS also achieved better lead times than before. The autumn season is when the LaserTrain is needed the most. Leaves and other contaminants are constantly sticking to the railhead. The devices had to make it from Amsterdam to the United States.

Other suppliers had lead times of 10 weeks or more. 3D Hubs was able to cut that lead time to just a few weeks. By cutting the production time, the parts had a chance to ship out to the recipients without any delays.

Contact 3D Hubs today for a CNC machining quote. Their professional team updates the website on a regular basis so that engineers can swiftly move through the uploading steps. Speak to their representatives whenever necessary. The Design for Manufacturing feedback works well for every engineer’s creative mind.

Find a Home-Based Business to Start-Up >>> Hundreds of Business Listings.